Ergonomic Machining Center Comes in 12 Variations; Offers 24/7 Operation

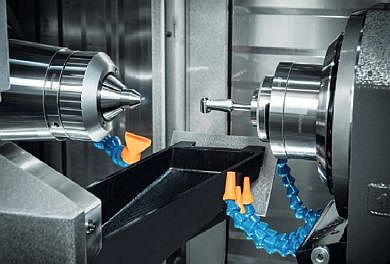

Starrag's new machining center is a redesign of the "191" flagship model from the Bumotec range. By combining all of the expertise inside a truly ergonomic enclosure, they have created the Bumotec 191neo.

With a large area of windows and perfectly positioned access doors, it provides unrivalled visibility of the different zones within the machine, and unmatched accessibility for all operators. Its touch display man-machine interface, developed from a Windows-based PC application, can be used to easily swipe between screens.

Amongst other functions, it can be used to monitor the progress of current machining operations, configure the programming, or track production in real time. In addition, the approach defined in conjunction with representative operators ensures training is user-friendly and intuitive also with the objective of reducing the level of skills of operators.

Precision Machining with 12 Different Faces

Available in four versions: "P" with vice, "PRM" with multipurpose pickup vice, "R" with back-working spindle, and "RP" with a combined vice and back-working spindle. It offers bar passage diameters of 42, 50 or 65 mm (1.6, 1.9, 2.5 inch).

Starrag is not just releasing one production solution. There are twelve (12) separate machines based on a single platform. The Bumotec 191neo provides a true economic and technical solution to both the current and future challenges arising from specific requirements relating to medical technologies, but also the luxury industry, and, more broadly, the micromechanics sector.

Tried and Tested Superior Performance

Extremely stable during production without any intervention from operators, the 191neo offers a formidable level of productivity. The tool change time, which has been reduced by 15%, further improves its response to the most demanding cycle time constraints.

To this is added the milling spindle with higher torque developed and produced by Starrag, and a back-working movement controlled by an electric motor, 12% faster and with rigid, precise position control. As has long been standard for Bumotec, its tool magazine has 90 positions and integrates now a tool breakage probe that runs in parallel.

Coupled with the now traditional Bumotec palletizer or with a robotic, modular or custom-made automated cell, this gives access to "24/7" type production, which is only interrupted by preventive maintenance when required.

Equipped with "à la carte" peripherals, such as a temperature-controlled, high-pressure chip conveyor and a Bumotec or other commercially-available bar loader known by their customers, the modular nature of the 191neo ensures all customer needs can be met. In addition to milling and turning, it can also be used for grinding, polishing, skiving, gear hobbing and diamond cutting, thereby allowing complex, demanding parts to be completed without changing fixtures.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::